Online G-Code generator for simple CNC hold-down clamp

This is simple online g-code generator which produces code for simple CNC hold-down clamp based on input parameters. I made this generator for learning purposes at moment, but I already have ideas to create some others also based on this code. Resulting G-Code should run well on grbl machines (tested).

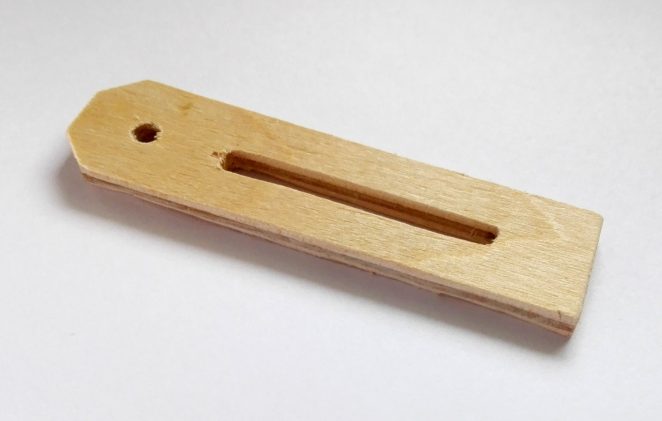

This is a simple CNC hold-down clamp which can be cut from sheet wood (like plywood). You can configure overall size, slot width, hole diameter and other measurements. I also included 2D and 3D preview in this post so you can play with parameters.

WARNING: I am not taking any responsibility for the generated G-code. Use it at your own risk / for reference only.

About this G-Code generator

You can change various parameters of the clamp in the form below and see instant results online. It generates g-code and also previews results interactively online. This should be straightforward and easy to use.

Keep in mind that resulting code assumes that minimum Z is CNC table zero. Material height is added on top of zero Z. So it starts cutting from positive (material height) until Z zero is reached. You can change this by applying negative Z offset in form. Same value as material height, but negative). Feed rate is fixed at moment, but you can change it later with simple search & replace in the file.

If slot width is smaller than tool diameter it will cut only straight line (no rectangular movements). If hole diameter is smaller than tool diameter it will drill a straight hole. This might not be visible on 2D preview. If a hole doesn’t fit on to clamp it might be skipped.

Lenght and width will be resulting size since this generator takes tool diameter into account.

3D view

3D rendering by ShopBotTools/G-Code-To-Geometry and threejs.org

G-Code

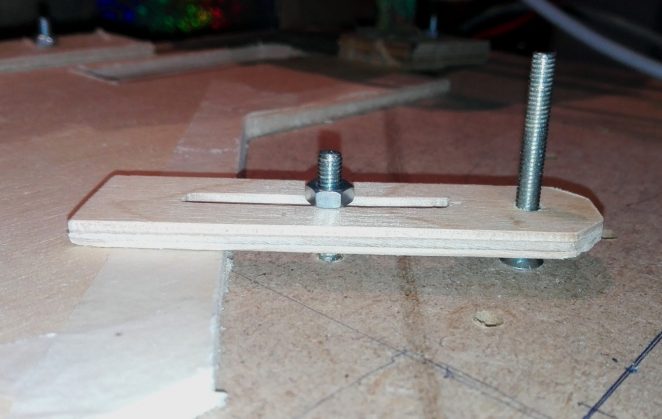

Photo of the end result – CNC clamp in use

Here is the picture of the clamp in use. It has a bolt through slot and CNC table and hole is for another bolt which is just for height adjustment (didn’t have a shorter bolt for this picture at moment). That second bolt is not actually needed, but it can be used so material and clamp would be in parallel. The real benefit comes from the slot/slit so you can adjust clamp perfectly to a workpiece. You can also check out video how this program runs on youtube (timelapse).